In the dynamic realm of fuel logistics, efficiency is paramount. Fuel terminals, often hubs of high activity, face the constant challenge of optimizing throughput while minimizing costs and maximizing safety. This demands a robust and intelligent approach to oversee operations, which is where terminal automation systems come into play. These cutting-edge solutions leverage technology to automate key processes, from fuel receipt and storage to transferring and tracking.

By automating tasks such as asset management, loading and unloading operations, and documentation procedures, terminal automation systems significantly enhance operational efficiency. Furthermore, they provide real-time insight into fuel levels, movements, and transactions, enabling informed decision-making and proactive response to potential challenges.

Advanced Gantry Robotics for Enhanced Tank Terminal Operations

Modern tank terminals require highly efficient operations to fulfill the ever-growing demands of the global energy market. Deploying intelligent gantry robotics offers a powerful solution to get more info streamline these processes, leading to improved safety, throughput, and productivity. These cutting-edge robotic systems possess the ability to advanced sensors and algorithms to faultlessly maneuver within tank farm environments, carrying out a wide range of tasks, including loading and unloading tankers, routing liquids between tanks, and conducting routine inspections. By mechanizing these tasks, intelligent gantry robotics de-burden human workers to focus on more complex activities, ultimately improving the overall success of tank terminal operations.

Seamless Flow, Maximum Efficiency: Automating Tank Terminals

In the dynamic landscape of energy and chemical distribution, tank terminals face increasing demands to optimize throughput. To meet these challenges, automation has emerged as a transformative solution, enabling seamless transit and maximizing efficiency. By integrating advanced technologies such as monitoring systems, control systems, and automated valves, tank terminals can achieve unprecedented levels of precision, repeatability, and safety.

- Automated tank gauging systems provide real-time data on fuel levels, minimizing manual intervention and ensuring accurate inventory management.

- Automation can handle repetitive tasks such as loading and unloading materials, eliminating labor expenses and improving worker safety.

- Advanced software platforms enable centralized control of terminal operations, providing valuable data for optimization of processes and resource allocation.

By embracing automation, tank terminals can achieve a significant leap in their operational efficiency, ultimately adding to the overall success and sustainability of their businesses.

Powering Progress: The Future of Automated Fuel Terminals

The future of automated fuel terminals is set to revolutionize the industry, offering streamlined efficiency and optimized safety. Utilizing cutting-edge technologies such as artificial intelligence, machine learning, and robotics, these terminals will automate key processes, spanning a range of activities such as inventory management and customer service.

This digitization will not only reduce operational costs but also {improvecustomer experience. Furthermore, automated fuel terminals will play a crucial role in implementing eco-friendly practices by minimizing accidents and leaks. The implementation of these technologies is gaining momentum, signaling a promising future for the fuel industry.

Automated Automation Solutions for Modern Fuel Handling Terminals

Modern fuel handling terminals face increasingly sophisticated automation solutions to streamline operational efficiency, safety, and compliance. Deploying smart automation technologies allows terminals to transform key processes such as fuel receipt, storage management, logistics control, and quality testing. This results in lowered operational expenses, improved accuracy, real-time data visibility, and increased overall safety within the terminal environment.

- Essential benefits of smart automation solutions include:

- Digitization of manual tasks, leading to higher productivity and minimized human error.

- Improved fuel control processes for efficient storage, distribution, and recording.

- Instantaneous data analytics and reporting for enhanced decision-making and efficiency monitoring.

Revolutionizing Terminal Operations with Integrated Automation Systems

Seamlessly optimize terminal operations by implementing cutting-edge integrated automation systems. These sophisticated solutions empower personnel to execute tasks with unparalleled accuracy, reducing manual intervention and minimizing the risk of human error. Automation enhances a range of critical operations, including container management, cargo inspection, and documentation procedures. By leverage these innovative systems, terminals can achieve significant gains in throughput, cost reduction, and overall operational effectiveness.

- Streamline container handling with automated cranes and guided vehicles.

- Optimize cargo sorting and processing with intelligent conveyor systems.

- Enhance documentation workflows with digital platforms and data integration.

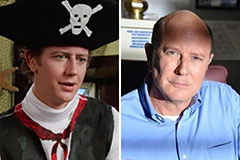

Emilio Estevez Then & Now!

Emilio Estevez Then & Now! Luke Perry Then & Now!

Luke Perry Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now!